Which Filler Metal Has The Highest Melting Point . This alloy must be capable of wetting the base. — the defining aspect of brazing is the melting of a filler metal in the joint; This alloy must be capable of wetting the base metal [1],. pure nickel is not widely used as a filler metal because of its high melting point, except for some certain applications, such. — the brazing thermal treatment melts the filler metal which interacts with the joint surfaces and the additive metal powder, allowing the boron to. the defining aspect of brazing is the melting of a filler metal in the joint; — during the brazing process, molten filler metal cools and solidifies to create a metallurgical bond between workpiece materials.

from www.youtube.com

the defining aspect of brazing is the melting of a filler metal in the joint; — the defining aspect of brazing is the melting of a filler metal in the joint; This alloy must be capable of wetting the base metal [1],. — during the brazing process, molten filler metal cools and solidifies to create a metallurgical bond between workpiece materials. This alloy must be capable of wetting the base. — the brazing thermal treatment melts the filler metal which interacts with the joint surfaces and the additive metal powder, allowing the boron to. pure nickel is not widely used as a filler metal because of its high melting point, except for some certain applications, such.

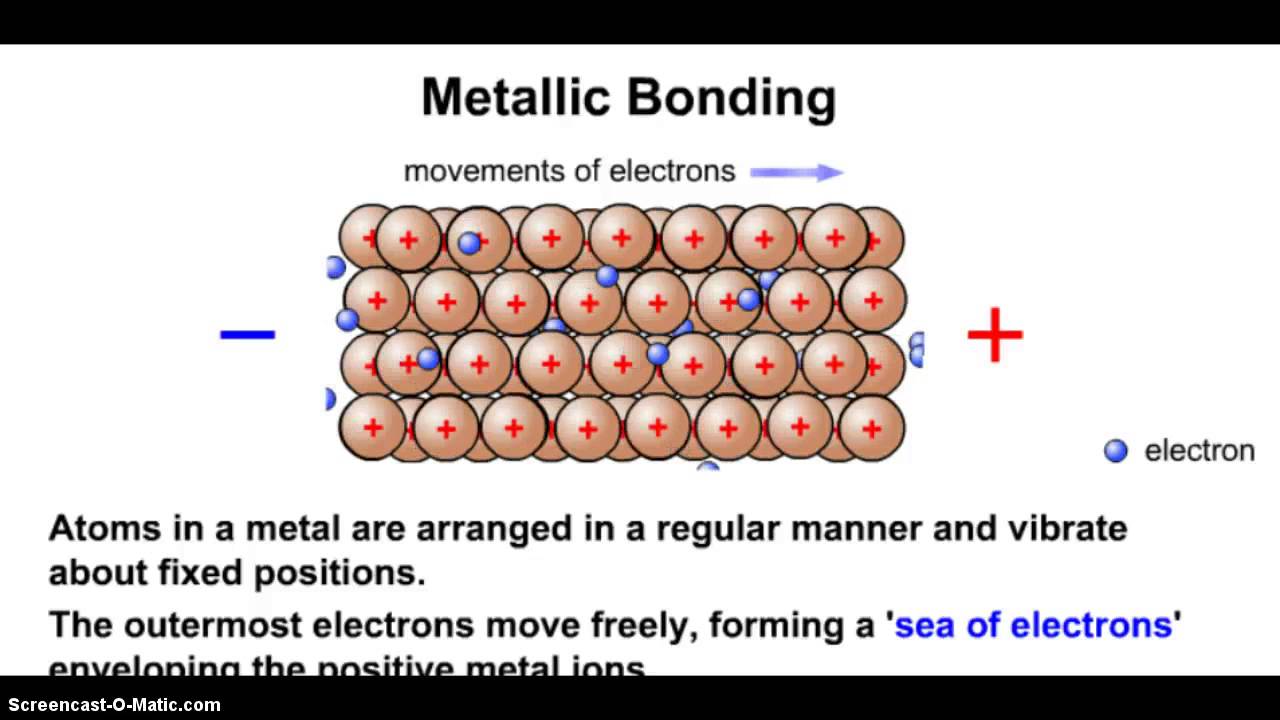

Melting Point Trends for Metals YouTube

Which Filler Metal Has The Highest Melting Point This alloy must be capable of wetting the base. — the brazing thermal treatment melts the filler metal which interacts with the joint surfaces and the additive metal powder, allowing the boron to. This alloy must be capable of wetting the base metal [1],. the defining aspect of brazing is the melting of a filler metal in the joint; — during the brazing process, molten filler metal cools and solidifies to create a metallurgical bond between workpiece materials. pure nickel is not widely used as a filler metal because of its high melting point, except for some certain applications, such. This alloy must be capable of wetting the base. — the defining aspect of brazing is the melting of a filler metal in the joint;

From www.refractorymetal.org

Metal with High Melting Point Top 10 Metals with High Melting Points Which Filler Metal Has The Highest Melting Point — during the brazing process, molten filler metal cools and solidifies to create a metallurgical bond between workpiece materials. — the brazing thermal treatment melts the filler metal which interacts with the joint surfaces and the additive metal powder, allowing the boron to. the defining aspect of brazing is the melting of a filler metal in the. Which Filler Metal Has The Highest Melting Point.

From www.scribd.com

All Metal Melting Points Metals Nickel Which Filler Metal Has The Highest Melting Point pure nickel is not widely used as a filler metal because of its high melting point, except for some certain applications, such. — the brazing thermal treatment melts the filler metal which interacts with the joint surfaces and the additive metal powder, allowing the boron to. — during the brazing process, molten filler metal cools and solidifies. Which Filler Metal Has The Highest Melting Point.

From www.nagwa.com

Question Video Determining Why Transition Metals have High Melting and Which Filler Metal Has The Highest Melting Point This alloy must be capable of wetting the base metal [1],. — the defining aspect of brazing is the melting of a filler metal in the joint; — during the brazing process, molten filler metal cools and solidifies to create a metallurgical bond between workpiece materials. the defining aspect of brazing is the melting of a filler. Which Filler Metal Has The Highest Melting Point.

From blog.thepipingmart.com

Tungsten's High Melting Point A Complete Guide Which Filler Metal Has The Highest Melting Point — during the brazing process, molten filler metal cools and solidifies to create a metallurgical bond between workpiece materials. This alloy must be capable of wetting the base metal [1],. — the defining aspect of brazing is the melting of a filler metal in the joint; pure nickel is not widely used as a filler metal because. Which Filler Metal Has The Highest Melting Point.

From www.refractorymetal.org

Metal with High Melting Point Top 10 Metals with High Melting Points Which Filler Metal Has The Highest Melting Point — the defining aspect of brazing is the melting of a filler metal in the joint; — during the brazing process, molten filler metal cools and solidifies to create a metallurgical bond between workpiece materials. pure nickel is not widely used as a filler metal because of its high melting point, except for some certain applications, such.. Which Filler Metal Has The Highest Melting Point.

From www.tes.com

Periodic Trends Metallic Bonding and Melting Points Teaching Resources Which Filler Metal Has The Highest Melting Point pure nickel is not widely used as a filler metal because of its high melting point, except for some certain applications, such. the defining aspect of brazing is the melting of a filler metal in the joint; — the brazing thermal treatment melts the filler metal which interacts with the joint surfaces and the additive metal powder,. Which Filler Metal Has The Highest Melting Point.

From www.nagwa.com

Question Video Identifying the Period 2 Element with the Highest Which Filler Metal Has The Highest Melting Point — during the brazing process, molten filler metal cools and solidifies to create a metallurgical bond between workpiece materials. the defining aspect of brazing is the melting of a filler metal in the joint; — the brazing thermal treatment melts the filler metal which interacts with the joint surfaces and the additive metal powder, allowing the boron. Which Filler Metal Has The Highest Melting Point.

From byjus.com

The highest melting point among alkali metal is Which Filler Metal Has The Highest Melting Point — the defining aspect of brazing is the melting of a filler metal in the joint; This alloy must be capable of wetting the base metal [1],. the defining aspect of brazing is the melting of a filler metal in the joint; — the brazing thermal treatment melts the filler metal which interacts with the joint surfaces. Which Filler Metal Has The Highest Melting Point.

From www.kapilsteels.com

Melting Points of Different Metals Which Filler Metal Has The Highest Melting Point — the brazing thermal treatment melts the filler metal which interacts with the joint surfaces and the additive metal powder, allowing the boron to. — the defining aspect of brazing is the melting of a filler metal in the joint; — during the brazing process, molten filler metal cools and solidifies to create a metallurgical bond between. Which Filler Metal Has The Highest Melting Point.

From sciencenotes.org

Melting Point Definition and List Which Filler Metal Has The Highest Melting Point the defining aspect of brazing is the melting of a filler metal in the joint; — during the brazing process, molten filler metal cools and solidifies to create a metallurgical bond between workpiece materials. — the brazing thermal treatment melts the filler metal which interacts with the joint surfaces and the additive metal powder, allowing the boron. Which Filler Metal Has The Highest Melting Point.

From www.youtube.com

Top 5 Metals that have Highest Melting Points in the world RK Which Filler Metal Has The Highest Melting Point the defining aspect of brazing is the melting of a filler metal in the joint; pure nickel is not widely used as a filler metal because of its high melting point, except for some certain applications, such. — the brazing thermal treatment melts the filler metal which interacts with the joint surfaces and the additive metal powder,. Which Filler Metal Has The Highest Melting Point.

From isaacjames.z13.web.core.windows.net

Melting Point Of Metals Which Filler Metal Has The Highest Melting Point the defining aspect of brazing is the melting of a filler metal in the joint; — during the brazing process, molten filler metal cools and solidifies to create a metallurgical bond between workpiece materials. — the defining aspect of brazing is the melting of a filler metal in the joint; pure nickel is not widely used. Which Filler Metal Has The Highest Melting Point.

From www.refractorymetal.org

Metal with High Melting Point Top 10 Metals with High Melting Points Which Filler Metal Has The Highest Melting Point — the brazing thermal treatment melts the filler metal which interacts with the joint surfaces and the additive metal powder, allowing the boron to. — during the brazing process, molten filler metal cools and solidifies to create a metallurgical bond between workpiece materials. pure nickel is not widely used as a filler metal because of its high. Which Filler Metal Has The Highest Melting Point.

From msestudent.com

17 Metals With the Highest Melting Points (and Why) Materials Science Which Filler Metal Has The Highest Melting Point pure nickel is not widely used as a filler metal because of its high melting point, except for some certain applications, such. — the brazing thermal treatment melts the filler metal which interacts with the joint surfaces and the additive metal powder, allowing the boron to. — during the brazing process, molten filler metal cools and solidifies. Which Filler Metal Has The Highest Melting Point.

From msestudent.com

17 Metals With the Highest Melting Points (and Why) Materials Science Which Filler Metal Has The Highest Melting Point pure nickel is not widely used as a filler metal because of its high melting point, except for some certain applications, such. This alloy must be capable of wetting the base metal [1],. the defining aspect of brazing is the melting of a filler metal in the joint; — the defining aspect of brazing is the melting. Which Filler Metal Has The Highest Melting Point.

From www.pinterest.com

Metals have a high Melting point. Metal working, Metal bending, Real Which Filler Metal Has The Highest Melting Point This alloy must be capable of wetting the base. pure nickel is not widely used as a filler metal because of its high melting point, except for some certain applications, such. — the defining aspect of brazing is the melting of a filler metal in the joint; This alloy must be capable of wetting the base metal [1],.. Which Filler Metal Has The Highest Melting Point.

From www.youtube.com

Melting Point Of Different Metals YouTube Which Filler Metal Has The Highest Melting Point This alloy must be capable of wetting the base metal [1],. — during the brazing process, molten filler metal cools and solidifies to create a metallurgical bond between workpiece materials. pure nickel is not widely used as a filler metal because of its high melting point, except for some certain applications, such. — the brazing thermal treatment. Which Filler Metal Has The Highest Melting Point.

From msestudent.com

17 Metals With the Highest Melting Points (and Why) Materials Science Which Filler Metal Has The Highest Melting Point pure nickel is not widely used as a filler metal because of its high melting point, except for some certain applications, such. — the defining aspect of brazing is the melting of a filler metal in the joint; This alloy must be capable of wetting the base. This alloy must be capable of wetting the base metal [1],.. Which Filler Metal Has The Highest Melting Point.